When it comes to modern construction, the strength and durability of building materials are of paramount importance. Among the various materials used in the construction industry, TMT (Thermo-Mechanically Treated) bars play a crucial role, especially in ensuring the structural integrity and long-lasting stability of buildings. One of the most significant attributes of TMT bars is their resistance to corrosion, a factor that is particularly important in regions with harsh environmental conditions. For builders, understanding the science behind corrosion resistance in TMT bars is essential for making informed decisions about material selection. In this article, we will delve into the science of corrosion resistance in TMT bars, focusing on why it’s critical for construction projects and what builders should consider when choosing the right TMT bars from reliable suppliers.

1. What Are TMT Bars?

Before exploring the science behind corrosion resistance, let’s briefly understand what TMT bars are. TMT bars are high-strength reinforcement bars that are manufactured using a special process called Thermo-Mechanical Treatment. This process involves subjecting the steel to a controlled heat treatment, which results in the formation of a tough outer layer while maintaining a soft inner core. This combination of high strength and flexibility makes TMT bars the go-to choice for modern construction, especially in high-rise buildings, bridges, and infrastructure projects.

The unique properties of TMT bars—strength, ductility, and resistance to corrosion—make them indispensable in ensuring the safety and longevity of structures.

2. The Science of Corrosion Resistance in TMT Bars

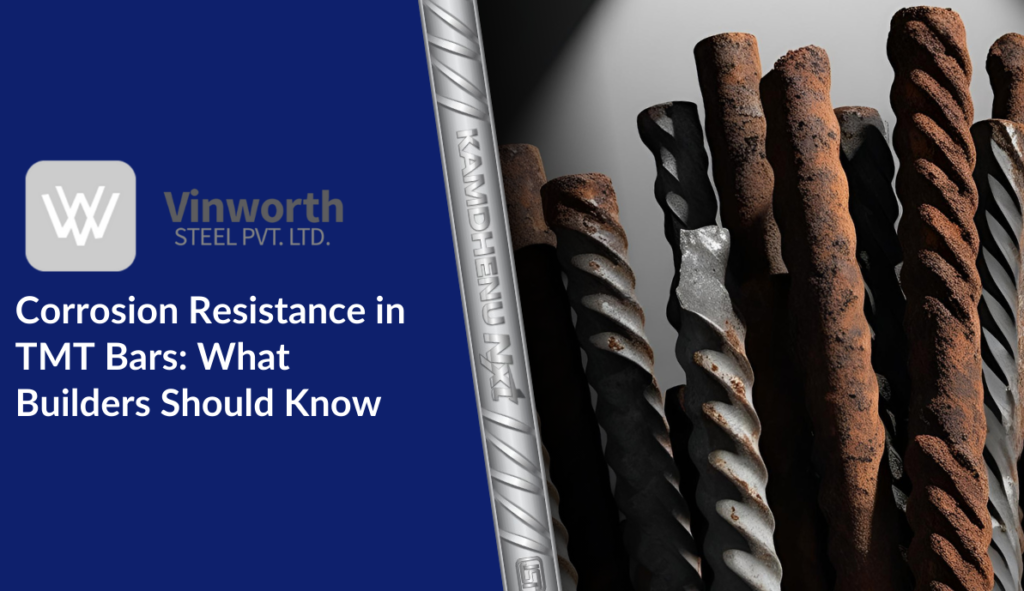

Corrosion is one of the most common and detrimental issues that affect the longevity of steel used in construction. It happens when the steel reacts with moisture, oxygen, and other elements in the environment, resulting in the formation of rust, which weakens the material over time.

TMT bars are designed with corrosion resistance in mind. The process of thermo-mechanical treatment increases the tensile strength of the bars while simultaneously enhancing their resistance to corrosion. Here’s how it works:

2.1 The Outer Layer: Hard and Dense

The key to corrosion resistance in TMT bars lies in the hard, dense outer layer that is formed during the quenching and tempering process. The outer layer is essentially a carbon-enriched martensitic structure that prevents moisture and air from coming into direct contact with the inner core of the steel. This hard outer layer forms a protective shield against corrosive agents, helping to maintain the integrity of the steel over time.

2.2 The Inner Core: Soft and Ductile

While the outer layer of TMT bars is hardened to resist corrosion, the inner core remains soft and ductile. This is crucial because the ductility of the inner core allows the bar to bend without breaking under stress. The soft core also provides better bonding with concrete, improving the overall strength and stability of the structure. This combination of a hard outer layer and a soft inner core is what gives TMT bars their unique ability to resist corrosion while maintaining structural integrity.

2.3 Alloying Elements: Enhancing Corrosion Resistance

To further enhance the corrosion resistance of TMT bars, manufacturers often incorporate specific alloying elements into the steel, such as chromium, copper, and nickel. These elements act as corrosion inhibitors, forming a protective oxide layer on the surface of the steel, preventing rust formation. By choosing TMT bars that contain these alloying elements, builders can ensure that their structures are better equipped to withstand the corrosive effects of environmental factors like moisture, salt, and chemicals.

3. Factors Affecting Corrosion Resistance in TMT Bars

While the manufacturing process of TMT bars plays a significant role in their corrosion resistance, there are several external factors that can impact their performance. Builders should be aware of these factors to make the best choice when selecting TMT bars from reliable suppliers.

3.1 Environmental Conditions

The most obvious factor affecting corrosion resistance is the environment in which the TMT bars will be used. Areas with high humidity, frequent rainfall, or proximity to saltwater are more prone to corrosion. For example, structures located in coastal regions or near industrial zones are at a higher risk of corrosion due to the presence of salt and other chemicals in the air. In such cases, opting for TMT bars with enhanced corrosion resistance, such as epoxy-coated TMT bars, can be a smart decision.

3.2 Quality of Concrete

Another important factor is the quality of concrete in which the TMT bars are embedded. Concrete acts as a protective layer around the steel, preventing direct exposure to moisture and air. However, if the concrete mix is of poor quality or lacks proper curing, it can allow water to seep in, leading to rust formation. Ensuring that the concrete is mixed and cured properly is essential for maximizing the corrosion resistance of the TMT bars.

3.3 Proper Handling and Storage

Proper handling and storage of TMT bars are also critical in preventing corrosion. Bars that are exposed to moisture before installation can develop surface rust, which may compromise their strength. Builders should store TMT bars in dry, covered areas to prevent exposure to rain or humidity before they are used in construction projects.

4. Epoxy Coating and Other Corrosion-Resistant TMT Bars

In addition to the natural corrosion resistance of TMT bars, there are other treatments and coatings available to further protect the steel from rust and degradation.

4.1 Epoxy-Coated TMT Bars

One of the most effective ways to enhance the corrosion resistance of TMT bars is by applying an epoxy coating. Epoxy-coated TMT bars are coated with a layer of epoxy resin, which provides an additional barrier between the steel and the environment. This coating prevents moisture and chemicals from coming into contact with the steel, significantly reducing the risk of corrosion. Epoxy-coated TMT bars are ideal for projects in high-moisture areas, such as coastal regions, sewage systems, or underground structures.

4.2 Stainless Steel and Other Corrosion-Resistant Alloys

Some TMT bars are manufactured using stainless steel or other alloys that inherently resist corrosion. These TMT bars offer an even higher level of protection against rust and degradation, making them suitable for extreme environmental conditions. Builders should consider these options for projects that require maximum durability and longevity.

5. Choosing the Right TMT Supplier and Distributor

When selecting TMT bars for a construction project, it’s crucial to choose a trusted and reliable TMT supplier and distributor. Consider the following important points:

5.1 Reputable Suppliers and Distributors

Working with reputable TMT suppliers and distributors, such as Kamdhenu TMT Bars, Kay 2 TMT Distributor, ET TMT Bars, and Electrotherm TMT Supplier, ensures that the quality of the TMT bars meets the required standards. A top TMT distributor will offer products that are certified by government bodies and have undergone rigorous testing to ensure they meet quality, strength, and corrosion resistance standards.

5.2 NHAI and Railway Steel Suppliers

For infrastructure projects like highways and railways, it’s essential to source TMT bars from suppliers who are approved by government bodies such as NHAI (National Highways Authority of India) and railway authorities. NHAI Steel Suppliers and Railway Steel Suppliers are trusted sources for TMT bars that meet the strict requirements for such projects.

5.3 Local and Specialized Suppliers

In regions like Gujarat, it’s beneficial to work with a South Gujarat TMT Distributor who understands local construction needs and environmental conditions. Local suppliers can offer products that are well-suited for the specific challenges posed by the region’s climate and terrain.

6. Conclusion

Understanding the science behind corrosion resistance in TMT bars is essential for builders who want to ensure the longevity and safety of their structures. Corrosion resistance in TMT bars is achieved through the use of advanced manufacturing techniques, alloying elements, and surface treatments like epoxy coatings. By choosing high-quality TMT bars from reputable suppliers and distributors, builders can mitigate the risks of corrosion and extend the lifespan of their construction projects. Whether it’s for residential buildings, bridges, or large infrastructure projects, the right TMT bars are key to building durable, safe, and long-lasting structures.

At Vinworth TMT Bar Distributors, we offer a wide range of high-quality TMT bars, including Kamdhenu TMT Bars, Kay 2 TMT, and Electrotherm TMT, ensuring that builders have access to the best products for their projects. Our TMT bars come with enhanced corrosion resistance, ensuring that your structures stand the test of time, no matter the environmental conditions. Contact us today to learn more about our products and how we can help you with your next construction project.